Bioplastics offer a smaller carbon footprint

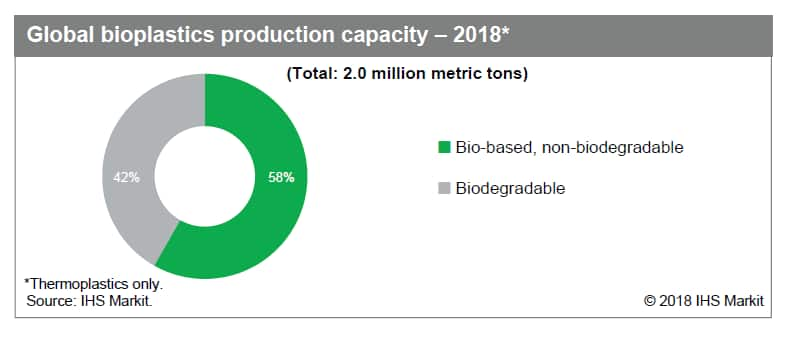

Bioplastics - polymers that are bio-based, biodegradable (compostable), or both - play a small but significant role in the world thermoplastics market. Currently bioplastics account for less than 1% of global thermoplastics production capacity. Polymers that are wholly or partially derived from renewable feedstocks, including bio polyethylene and bio polyethylene terephthalate (PET), are responsible for 58% of production capacity. Biodegradable (compostable) polymers make up the remainder. Many compostable polymers, including polylactic acid and starch/ copolyester compounds, are bio-based (at least in part) in addition to being biodegradable.

Nondurable applications dominate bioplastics consumption. Important end uses include cold cups, beverage bottles, food containers, disposable utensils, shopping bags, and garbage bags. Durable applications include carpet yarns (in the case of polytrimethylene terephthalate) and air-brake tubing (in the case of polyamide 11).

How do bioplastics contribute to sustainability?

First, because most bioplastics are derived at least in part from corn, sugarcane, or other plants, they have a smaller carbon footprint, with lower cradle-to-plant-gate greenhouse gas emissions than their fossil fuel-based counterparts. At least one bioplastic, polyamide 410, is carbon neutral: its cradle-to-plant-gate-greenhouse gas emissions are zero. The amount of carbon dioxide generated during the manufacture of polyamide 410 - which comes from a combination of renewable feedstocks derived from castor bean oil and petrochemical feedstocks - is offset by the amount of carbon dioxide absorbed during the growth of the castor bean plant.

Second, bioplastics facilitate composting, thus diverting food remains, yard clippings, and other organic waste from landfill. Diversion of organic waste reduces emissions of methane, a potent greenhouse gas formed as a by-product of waste decomposition in landfills. Clamshells, cups, and single-serve coffee capsules made of biodegradable polylactic acid can be composted along with leftover food in industrial compost facilities. Garbage bags made of biodegradable starch/copolyester compounds reduce the "ick factor" associated with composting food waste.

Third, some (but not all) bioplastics are fully compatible with the existing plastics recycling infrastructure. From a chemical perspective, bio PET and bio high-density polyethylene (HDPE) are identical to their fossil fuel-based counterparts. Soft drink bottles made of bio PET or bio HDPE pose no threat to the quality of PET and HDPE post-consumer recycle streams.

Do bioplastics offer a solution to the highly visible problem of ocean plastic waste?

No. Few commercial bioplastics decompose completely in the environment. Preferred end-of-life options for bioplastics include industrial composting or recycling. Sadly, because of the lack of composting infrastructure and low recycling rates, bioplastics (like conventional plastics) often end up in landfill or incinerators.

Why do bioplastics remain niche products in the global thermoplastics market? Bioplastics can be more expensive than their conventional counterparts. In addition, production volumes are comparatively limited, with only a few sizable manufacturers for each bioplastic. Applications development is ongoing, especially in the case of some new bioplastics, and end users are still learning how to take full advantage of the materials' unique performance attributes.

Could bioplastics play a larger role in sustainability initiatives? Yes, but a major increase in the use of bioplastics seems unlikely in the absence of government mandates. A case in point: French demand for bioplastics increased after the government exempted compostable bio-based plastic bags from its 2017 ban on plastic shopping and produce bags. But bans on conventional plastic shopping bags and other single-use items do not automatically result in increased demand for bioplastics. Consumers have other environment-friendly alternatives, such as reusable shopping bags. Bioplastics will continue to compete for market share as the world grapples with the issue of plastics sustainability.

***

Plastics sustainability is the most critical issue facing the plastics industry and is likely to lead to greater regulation (including bans) and deselection by consumers, retailers & brand owners. A Sea Change: Plastics Pathway to Sustainability special study helps stake holders move progressively to understand the issues of plastics sustainability with extensive analysis and data quantifying the impacts. For more informaton, visit www.ihsmarkit.com/plastics