GHG emissions reduction modelling at Cambo field with QUE$TOR

Reducing greenhouse gas (GHG) emissions from the Cambo field can be achieved by using QUE$TOR™, the leading upstream cost estimation software that helps identify emissions sources and assess alternative design solutions.The Cambo field is estimated to produce a significant amount of combustion emissions from fuel gas. Using innovative technologies, it is possible to substantially reduce fuel gas consumption and lower the total emissions from the field.

The Cambo field, located in the UK North Sea Faroes-Shetland Trough approximately 120 km northwest of the Shetland Islands, has recently been in the spotlight due to the field's potentially large carbon footprint. During its expected production life of more than 25 years, Cambo is estimated to make a large contribution to the UK domestic energy market, helping to reduce hydrocarbon imports, and supporting Britain's energy security strategy. In 2022 the British oil and gas regulator approved a two-year license extension for the Cambo field, which allowed the operator more time to assess future options for the development. Meanwhile, environmental groups have created several petitions, and maintained active social awareness campaigns, with the mission to stop the development of the Cambo field.

S&P Global cost estimation tool QUE$TOR™ allows the estimation of GHG emissions which include direct production and surface processing related emissions, as well as indirect emissions from operational support activities at the project and activity level. QUE$TOR™ reports individual sources of emissions such as combustion, flaring, venting, and fugitives.

To investigate ways to reduce total lifecycle emissions and identify field development alternatives for Cambo, three scenarios were created using the QUE$TOR™ tool.

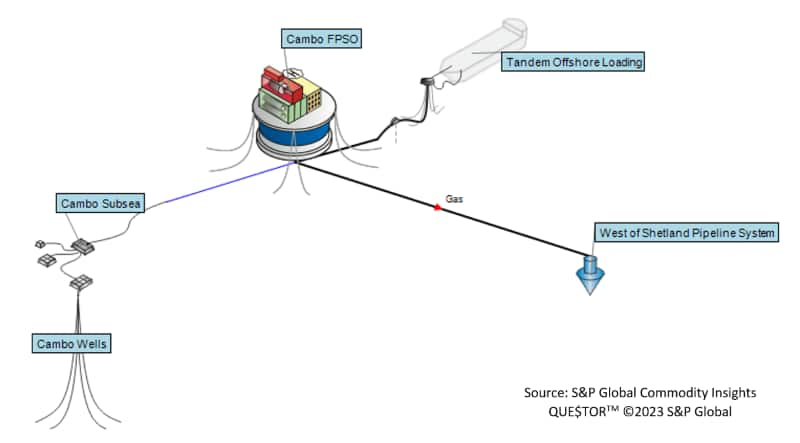

The base case scenario for Cambo, graphically represented below, consists of a dedicated FPSO, a subsea drill centre with nine production wells and four water injection wells. For product export, the model accounts for a dedicated gas export line whilst liquids are assumed to be offloaded. Total production is estimated to be 145 million barrels of oil equivalent.

For a reasonable comparison with published information, a theoretical constant fuel gas consumption profile is assumed for the entire production life of the field, reflecting the assumptions stated on Cambo's Environmental Impact Assessment (EIA) document (1).

From this base case, two more scenarios were created. Details for all scenarios are described below.

Scenario 1 | Base case. Facilities are assumed to be powered by own gas fuelled power generator. All topsides systems are using electric drivers and a waste heat recovery unit (WHRU) is included for the capture of waste heat generated from gas turbines. The recovered heat is used in place of fuel gas to provide the heating medium requirement. |

Scenario 2 | Base case + Offshore floating wind farm. The offshore wind farm includes the wind turbine and tower, floating substructure, mooring system and anchors, array cable, and onshore operations base. The wind farm is assumed to power 45% of Cambo's total power requirement and is connected to the topsides through a subsea power cable. The remainder 55% of required power is assumed to be supplied by own fuel gas. |

Scenario 3 | Base case + Power from shore. The power from shore is delivered by a redundant 125 km subsea power cable, that provides 100% of Cambo's power requirement. The emissions produced from onshore electricity generation are accounted for by applying an emission factor for generated electricity (supplied to the grid, plus imports)(2) of 0.191 kgCO2/kWh. |

Results of the scenario modelling in QUE$TOR™

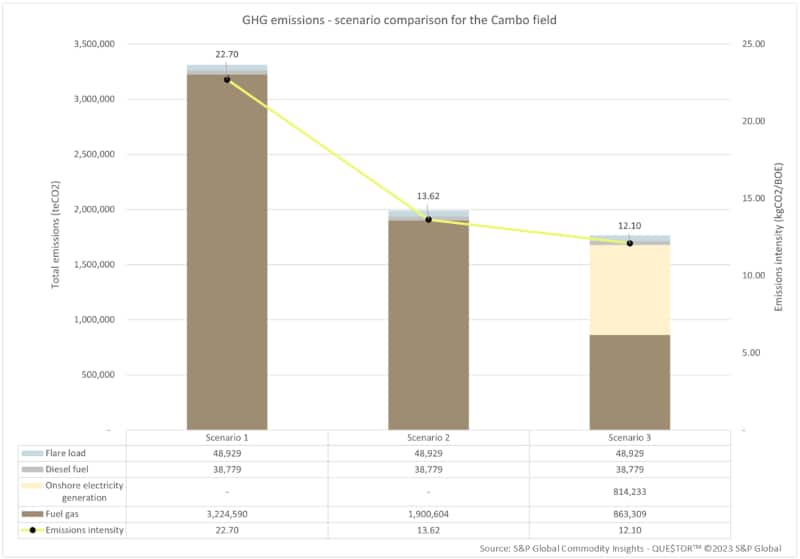

QUE$TOR™ GHG estimation capabilities include CO2 and CH4 emissions for combustion, flaring, and venting and fugitives. The estimation of emissions for this exercise is based on CO2 emissions only, since they represent the largest contribution to overall lifecycle GHG emissions of Cambo. Analysing the results of the estimations, effective reduction in total CO2 emissions for the Cambo field is observed in both Scenarios 2 and 3, using QUE$TOR™ estimation capabilities.

- Total CO2 emissions estimated by QUE$TOR™ for Cambo's base case are 3.31 million teCO2.

- Using an offshore floating wind farm to power a portion of Cambo's facilities, as described in Scenario 2, resulted in a reduction of 40% in total CO2 emissions for the field.

- Using a power cable from shore to power Cambo's facilities, as described in Scenario 3, resulted in a reduction of 47% in total CO2 emissions for the field.

A substantial portion of the emissions from Cambo are combustion emissions from fuel gas. With each investigated scenario, it has become clear that the use of the above technologies makes a major contribution to reduce fuel gas consumption, hence lowering the total emissions from the field.

Installing an offshore wind farm to partially meet the power requirements of Cambo's facilities results in a considerable drop of total lifecycle emissions. This type of solution has become more attractive for renewable energy integration projects, especially considering the UK is one of the leading countries in offshore wind technology. There is also the benefit of potentially using an offshore wind farm to power neighbouring facilities in the area.

According to our analysis, a power from shore solution is the most effective in reducing Cambo's lifecycle emissions. Fuel gas emissions are reduced to nearly 75% less than Base case. While this reduction in fuel gas emissions is certainly an optimistic indication, there are still uncertainties associated with the estimation of the onshore electricity generation emissions. The emission factor used in this analysis represents a country level average, which includes power generation from various sources. For this scenario to be considered a viable solution for Cambo, a deeper assessment of the specific onshore power generation source will be required. The increase in power demand from the project may result in a rise of emissions from gas-generated electricity, which can make lifecycle emissions for this scenario higher than those of Scenario 2.

In conclusion, from a carbon footprint reduction point of view, there are design alternatives available that offer a more environmentally friendly solution for the Cambo field. Reducing the total lifecycle emissions of the field is a major step towards complying with stakeholder expectations, but it is also imperative to thoroughly analyse the cost implications of these scenarios to make an informed final decision. By carefully assessing different design alternatives during the early stages of valuation and considering the technical feasibility and economic viability of each scenario using QUE$TOR™, we can achieve the optimal project design.

To ask questions, see a demo and learn more about QUE$TOR™ please contact ci.support@spglobal.com (S&P Global Commodity Insights Customer Care)

References:

1 - Cambo Oil Field, UKCS Blocks 204/4a, 204/5a, 204/9a and 204/10a. Environmental Impact Assessment (EIA). Siccar point Energy. June 2020.

2 - 2022 Government greenhouse gas conversion factors for company reporting: Methodology paper. Department for Business, Energy & Industrial Strategy, UK. June 2022.

This article was published by S&P Global Commodity Insights and not by S&P Global Ratings, which is a separately managed division of S&P Global.