Modified black oil properties a practical treatment of gas condensate and volatile oil PVT

The modified black oil PVT model allows reservoir engineers to account for complex PVT behavior that arises in gas condensate and volatile oil reservoirs.

Gas-Condensate and Volatile Oil systems contain gas which may have non-negligible amounts of vaporized liquid hydrocarbons, and this may have a significant impact on fluid behavior. Nowadays, the increasing price of liquid hydrocarbons compared to the gas price has raised more interest in improving the modeling of these reservoirs and for devising better tools for more realistic forecasts of surface liquid yields.

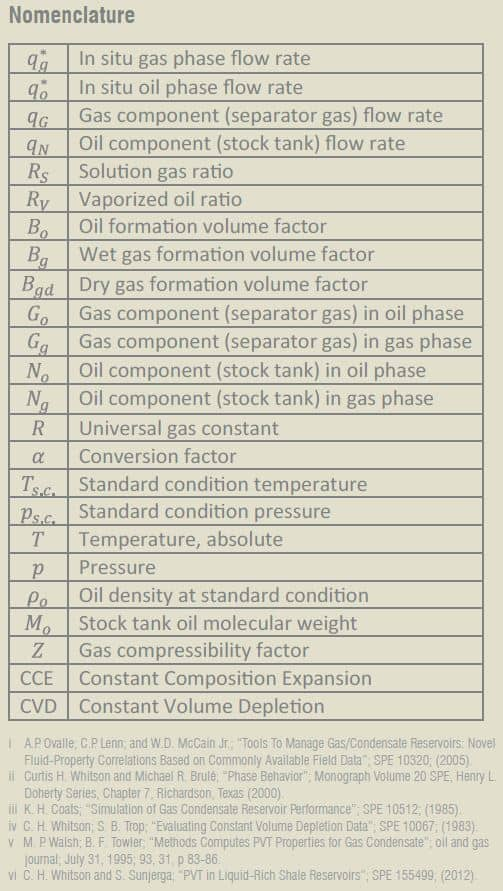

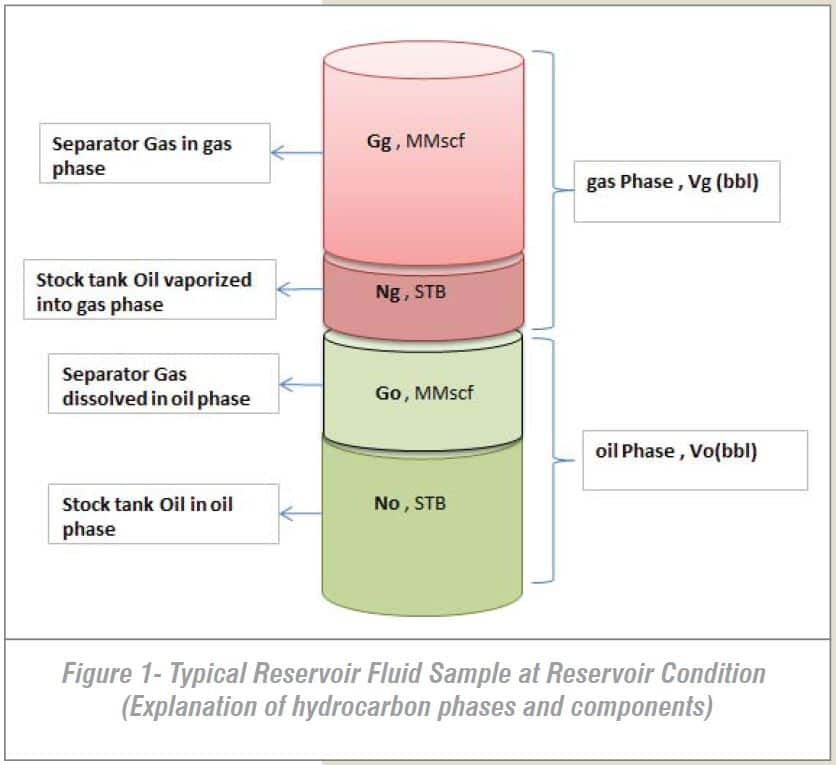

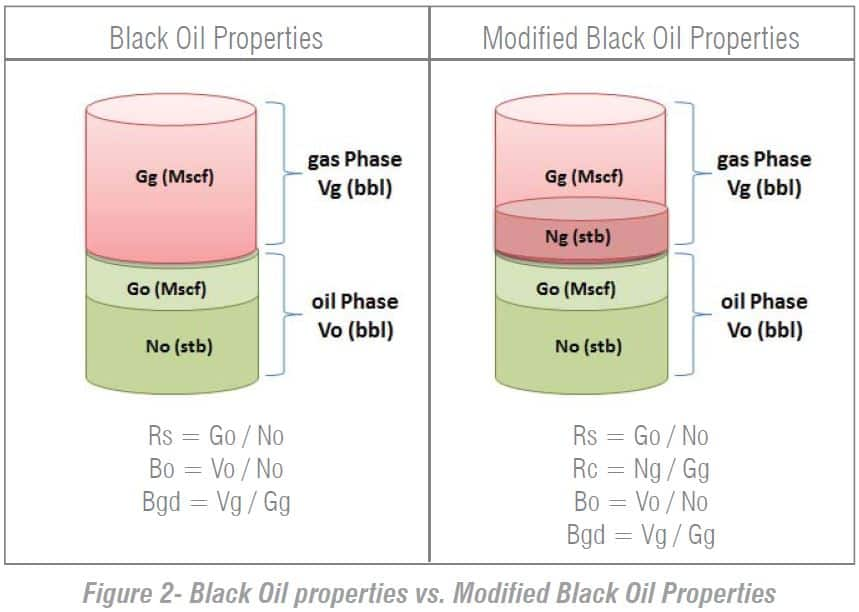

Common black oil properties do not consider the liquid hydrocarbon content of the gas phase. Black Oil properties have been well-defined and applied in different areas of modeling and analysis; however modified black oil properties for usage with gas condensate and volatile oil have been largely overlooked. In the modified black oil model, two new properties are needed; vaporized oil ratio (Rv) and dry gas formation volume factor (Bgd). To explain these new properties, first consider Figure 1, which illustrates the distribution between the phases at given reservoir conditions.

Excluding water, in both black oil and modified black oil modeling, it is assumed that there are two components (separator gas (G) and stock tank oil (N)) and two phases (gas phase (g) and oil phase (o)); each of the components can exist in either phase. The amount of the produced gas at the separator is the summation of gas component that comes from of the gas phase (Gg), and the gas component that comes from the oil phase (dissolved gas, Go). Likewise, the stock tank oil (N) comes from both the oil phase (No) and the gas phase (vaporized oil, Ng). In the conventional black oil properties the Ng is neglected (Figure 2).

Vaporized Oil Ratio (Rv) and Dry Gas Formation Volume Factor (Bgd):

Analogous to the solution gas ratio (Rs) in the oil phase, the vaporized oil ratio (Rv) is defined in the gas phase. Physically, if a gas sample at reservoir conditions is brought to standard conditions, "Rv" describes the volume of oil (condensate) that will be produced, given a certain volume of separator gas (see Figure 2). For a specific rich-gas system, the vaporized gas ratio (Rv) is a function of pressure, temperature and separator conditions.

There are only few correlations for estimating “Rv”. We assessed all of the available correlations qualitatively and the "Rv" correlation that was chosen for Fekete’s software was Ovalle et al.’s correlation (2005)i. This correlation showed more reasonable responses to the controlling parameters (i.e. reservoir temperature, oil API gravity and separator conditions).

The other distinct modified black oil property is the dry gas formation volume factor (Bgd). Before any discussion, we need to distinguish between wet gas formation volume factor (Bg) and “Bgd”. Referring to Figure 1, the wet gas formation volume factor is the ratio of the gas phase at given pressure and temperature (Vg) to the equivalent volume of the whole gas phase at standard condition; however, the dry gas formation volume factor (Bgd) is the ratio between the volume of gas phase at given conditions (Vg) to the volume of its Gas component (Gg) at standard conditions. In conventional black oil applications, “Ng” is zero, which causes “Bgd” and “Bg” to become the same. However, for modified black oil applications, we need to differentiate between “Bg” and “Bgd”. Although there is no correlation available for "Bgd", it can be calculated simply by using the following relationship between “Bg” and “Bgd”ii:

This equation also shows that if the "Rv" is zero (as in conventional black oil); the "Bg" and "Bgd" are equal. Though the calculation of "Bg" is as easy as the equation shown below, the gas compressibility factor "Z" is a function of gas specific gravity which itself is a function of the liquid content of the gas "Rv". Therefore, since the gas specific gravity and the "Z" factor may not be constant in modified black oil properties, the "Bg" needs to be updated accordingly.

Another complication that we track is the effect of the degree of gas saturation on "Bgd" as described by the dew point pressure. This is analogous to computing "Bo" in the oil case, where the bubble point pressure is used to distinguish between saturated and undersaturated oil. For calculating "Rv" and "Bgd" from conventional laboratory tests, Coat (1985)iii and Whitson and Trop (1983)iv have suggested two compositional algorithms using equation-of-state (EOS) modeling. In both algorithms, the EOS model should be tuned based on the available PVT tests. Unfortunately, the oil phase properties (“Bo” and “Rs”) obtained by these two methods are not reliable due to the error in the EOS-calculated oil density. Furthermore, for gas condensate, there is no measurement of oil density during CCE and CVD experiments to be used for volume shift corrections.

For gas condensates, Walsh and Towler (1995)v presented another procedure which is based on the material balance calculation. This procedure does not use EOS modeling; it uses only the measured quantities from a CVD test. IHS has improved upon this method and has developed a workflow to calculate all the modified black oil properties simultaneously only based on the results of CVD and CCE tests. The procedure honors both material balance and consistency checks.

Applications:

All the current numerical models in IHS Harmony™ are black oil models. Therefore, the simulation results for gas condensates and volatile oil reservoirs may not be fully accurate in some cases. Particularly for gas condensate reservoirs, the black oil numerical models cannot predict the condensate drop-out in the reservoir, which affects both condensate surface yield and well productivity. The modified black oil numerical simulator is currently under development and will be added to the existing numerical models in IHS Harmony™.

The current analytical models, on the other hand, have the ability to provide a split condensate forecast based on “Rv”. One assumption of this feature is that the bottomhole pressure is the controlling pressure for splitting the condensate from dry gas, in conjunction with “Rv” functionality. Numerical simulations (both compositional and modified black oil simulations) (Whitson, 2012)vi verified that this is a reasonable assumption. Although the analytical models cannot simulate the liquid drop-out around the wellbore nor its influence on flow hindrance, they can mimic it using the existing feature of changing skin with time.

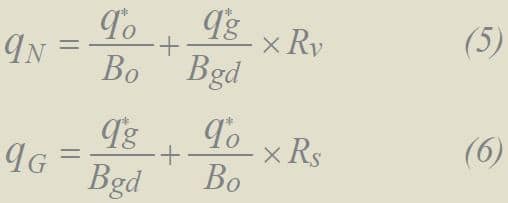

In wellbore and pipeline multiphase calculations, it is important to have a good estimation of liquid hold-up and also in-situ rates of different phases at any pressure and temperature. Consequently, “Rv” can be used here. The difference between the gas phase liquid contents (Rv) at two ends of any segment of the pipe is the indication of liquid hold-up in that segment. For calculations of the in-situ rates, we need to recall the concept of material balance of oil- and gas-components all along the wellbore or any pipe. At any point along a pipeline, we know that the total amount of the oil- and gas-components are the same; the only thing which is different is their distribution in terms of oil and gas phases.

By rearrangement, the in situ rates of the gas and oil phases at each location of the pipe can be calculated as:

In summary, the inclusion of modified black oil properties will provide significant benefits across IHS Engineering suite of software, while maintaining ease of use and practicality. For IHS RTA and IHS WellTest, it will allow us to simulate liquid dropout and associated productivity loss in retrograde condensate and volatile oil reservoirs. In IHS VirtuWell it will allow us to account for the condensation of hydrocarbon liquids within the wellstream, prior to reaching the separator, thereby providing more reliable pressure loss predictions. In IHS Piper it will allow us to account for liquid holdup due to condensate dropout in pipelines.

Mohammad Rahmanian, Fekete Associates Inc.

Posted 16 December 2015

This article was published by S&P Global Commodity Insights and not by S&P Global Ratings, which is a separately managed division of S&P Global.