Biodegradable Polymers: Contributing to a Sustainable Future

Biodegradable polymers are plastics that undergo microbial decomposition to carbon dioxide and water within specific time limits. These polymers may be 100% bio-based (that is, derived from renewable feedstocks such as corn, sugarcane, wood, or vegetable oil), 100% petrochemical-based (that is, derived from fossil fuels such as oil or natural gas), or anything in between.

At present, biodegradable polymers represent a small part of the global thermoplastics market. In 2020, global consumption of biodegradable polymers made up less than a quarter of one percent (less than 0.25%) of total thermoplastics consumption. Nonetheless, their potential to contribute to a more sustainable future is significant. The use of biodegradable polymers in shopping bags, drinking straws, coffee capsules, mulch films, and other hard-to-recycle applications can prevent plastic waste in the environment, support the diversion of organic waste from landfill, and reduce our carbon footprint.

To be clear, biodegradable polymers are not the only path to sustainability. We will need every tool in the toolbox—including chemical and mechanical recycling of conventional thermoplastics—to build a waste-free circular economy. Biodegradable polymers are an integral part of the tool kit.

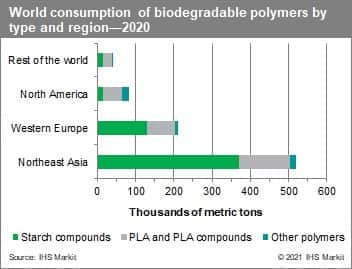

Starch compounds dominate global demand for biodegradable polymers, which totaled 854,000 metric tons in 2020. Most starch compounds are combinations of corn starch and polybutylene adipate terephthalate (PBAT), sometimes with a small amount of polylactic acid (PLA). Second in importance is PLA and its compounds, typically with PBAT. As the bar chart shows, the preference for starch compounds is especially strong in the two largest consuming regions—Northeast Asia and Western Europe. In North America and the rest of the world, the preference is for PLA and its compounds.

Northeast Asia—Mainland China, Japan, South Korea, and Taiwan—has the highest consumption growth rate: greater than 37%/year on average during 2020-25. For comparison, the predicted consumption growth rate for the world is almost 29% during the forecast period. The expected consumption growth rates in other regions are 5-7%/year on average.

Food packaging and bags are the major end uses for biodegradable polymers. Within the food packaging category, the largest application is shopping bags; other applications include produce bags and food service ware—cold cups, drinking straws, utensils, and clamshell containers. Compost bags—bin liners and garbage bags—make up the second largest end-use category. Although shopping and produce bags often have a second life as organic waste bags, they are not included in this category.

The main demand drivers for biodegradable polymers are regulations and corporate initiatives. In this context, "regulation" usually means "ban". National bans on plastic shopping bags, notably in Europe and Mainland China, drive demand for biodegradable polymers in those regions. Other bans target produce bags, drinking straws, utensils, and other single-use plastic products. Regulations that prohibit food and yard waste in landfill support the consumption of compost bags made of biodegradable polymers.

Corporate sustainability initiatives also drive demand. In response to consumer interest in environment-friendly products, major companies have switched to biodegradable drinking straws, compostable hot cups, biodegradable tea bags, and compostable coffee pods, all made with biodegradable polymers.

The biodegradable polymers industry faces formidable challenges, including:

- Lack of industrial composting infrastructure. Most biodegradable polymer products require industrial composting at the end of life; few are suitable for home compost piles. Many places lack infrastructure for industrial composting, including organic waste segregation and collection systems as well as composting facilities that can process both food and yard waste.

- Anaerobic digestion of organic waste. Increasingly, organic waste is processed in anaerobic digestion plants to produce biogas for energy. Some anaerobic digestion plants are incapable of processing compostable plastics.

- Incomplete biodegradation of biodegradable polymers under "real world" conditions, as opposed to laboratory test conditions. Process modifications such as longer processing times for composting may be necessary.

- Education. Recycling plastics has become a way of life for many consumers and businesses; composting organic waste is at an earlier stage of adoption.

Despite these challenges, biodegradable polymers have a role to

play in addressing global sustainability issues. To paraphrase

David Attenborough, we have an obligation to future generations to

leave behind a planet that is healthy and habitable for all.

Biodegradable polymers are part of the solution.

The latest market developments are available on the new update of

Biodegrable Polymers Chemical Economic Handbook.

Get Expert Content OnDemand from IHS Markit Global Plastics Summit, the leading plastics conference in the world bringing together industry and IHS Markit in strategic dialogue.