Practical recommendations and observations for production data analysis of conventional wells in rate transient analysis

Interpretation of production data using Rate Transient Analysis (RTA) depends heavily upon the quality of the production data, the validity of the fluid properties, and the proper application of the analysis method.

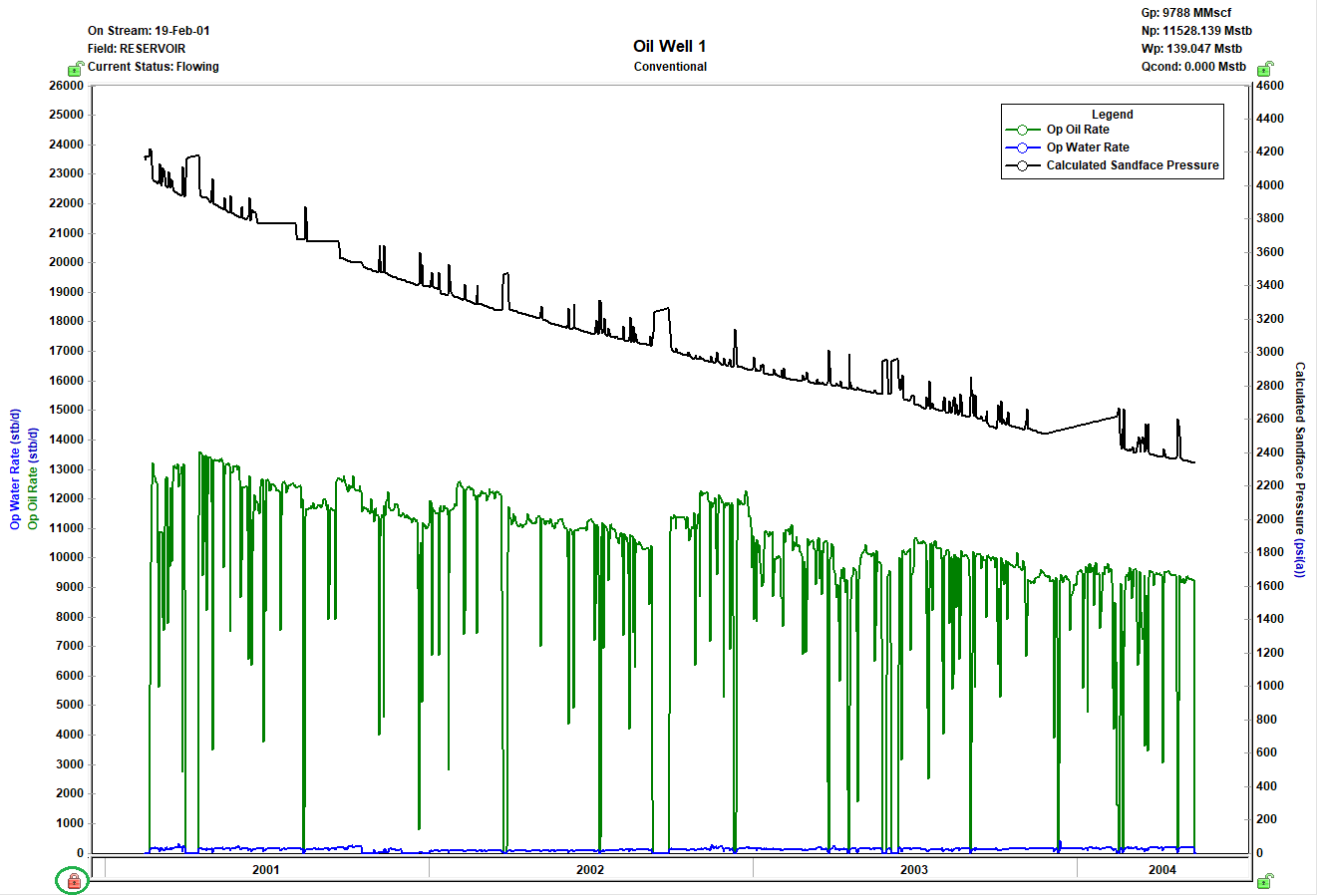

Figure 1: Oil Well 1

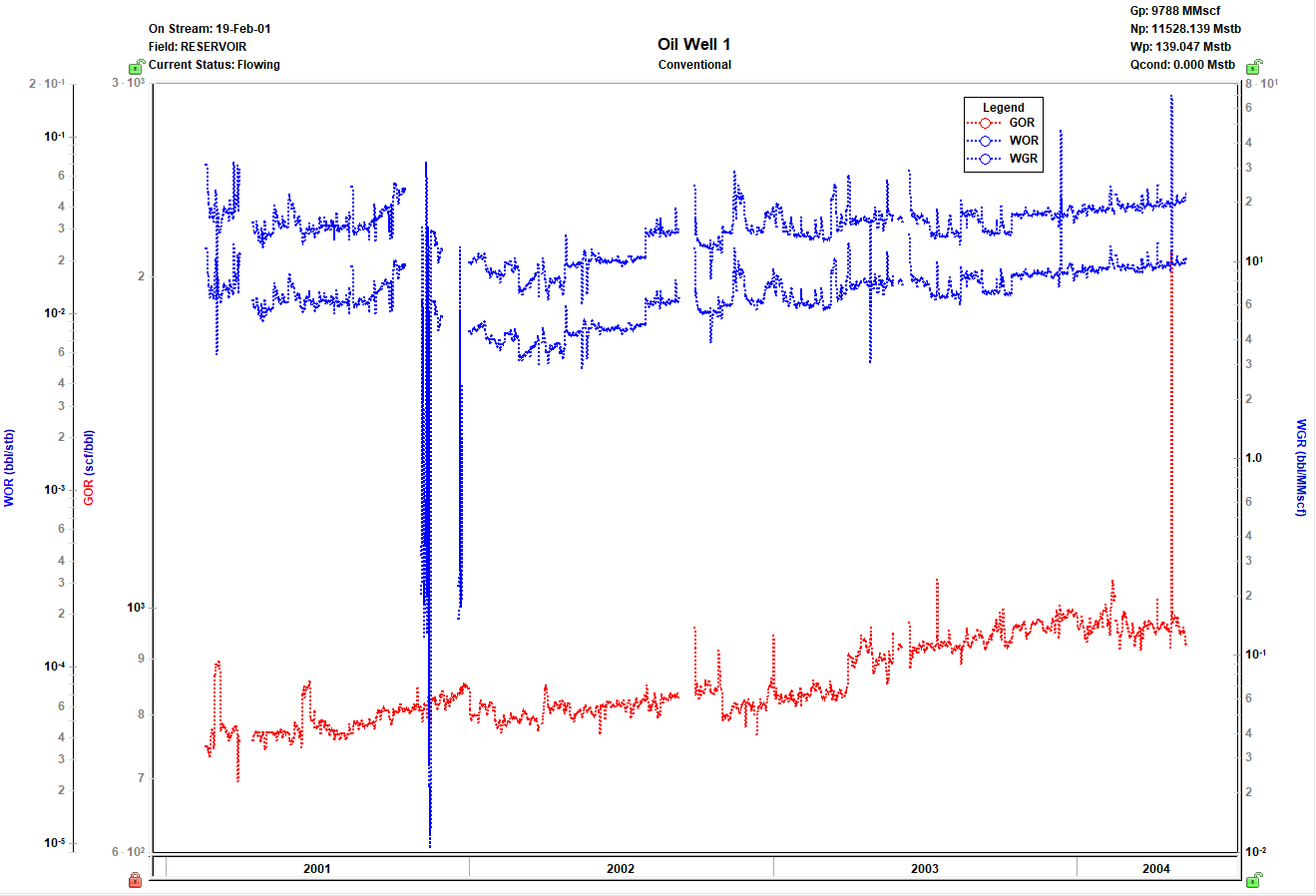

Figure 2: Oil Well 1

Figure 2: Oil Well 1

Data Quality Diagnostics: Production data can be affected by inconsistencies in data measurement or reporting. Some of the most common data problems include: infrequent, inaccurate or non-existent flowing rates and pressures, extrapolated or wrongly averaged flowing rates, or wrong initial reservoir pressure. There can be synchronization issues such as the flowrate continuing part-way into a shut-in, or pressures continuing to build after flow has recommenced. Another inconsistency observed occasionally, is that the flowrate increases, but there is no apparent change in the flowing pressure or worse, the flowing pressure goes up too. Any inconsistent data must be filtered from view prior to analysis.

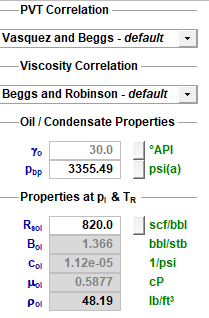

Reservoir Properties and PVT Properties: Confirm the validity of oil PVT properties by comparing the producing gas-oil-ratio (GOR) with the solution gas-oil ratio (Rs), taking into consideration the initial pressure, bubble point pressure and flowing pressures.

Figure 3: PVT Correlation

Static Pressure: Static pressure is recorded in a well after it has been shut-in for a period of time. It is subject to inaccuracies caused by incompletely built-up pressures or incorrect extrapolations. When used for material balance calculations, these inaccuracies can result in substantial errors in the calculated hydrocarbon-in-place.

Wellbore considerations: In the wellbore calculations of wellhead-to-bottomhole pressures, not only is it important to ensure that the right correlation is being used, but also that the fluid rates are correct - often water rates are not reported, yet even small (unreported) quantities of water in the gas flow stream can make a significant difference in the calculated pressures. With certain wellbore configurations, calculations down the "quiet side" can be significantly more accurate than those down the "flowing Path".

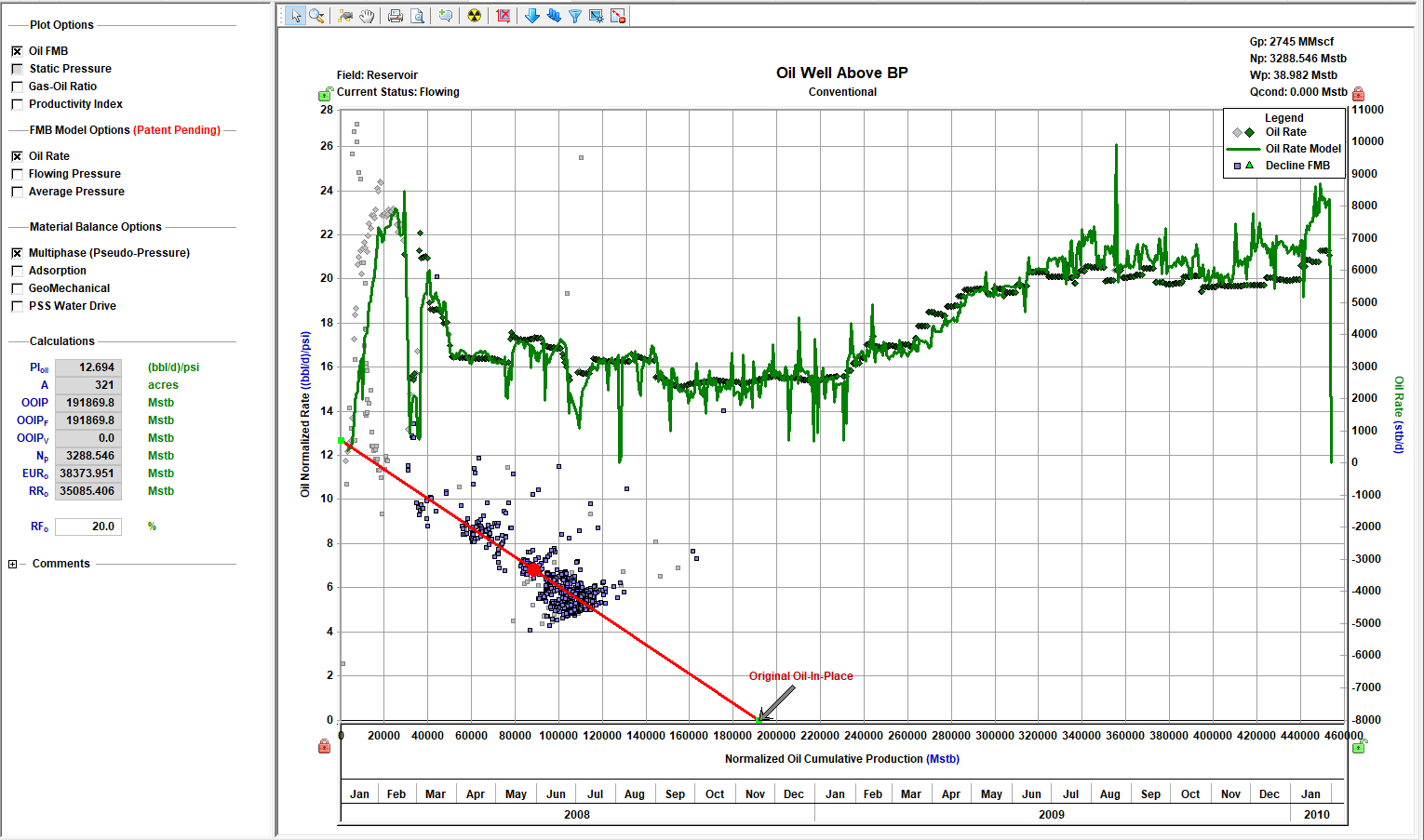

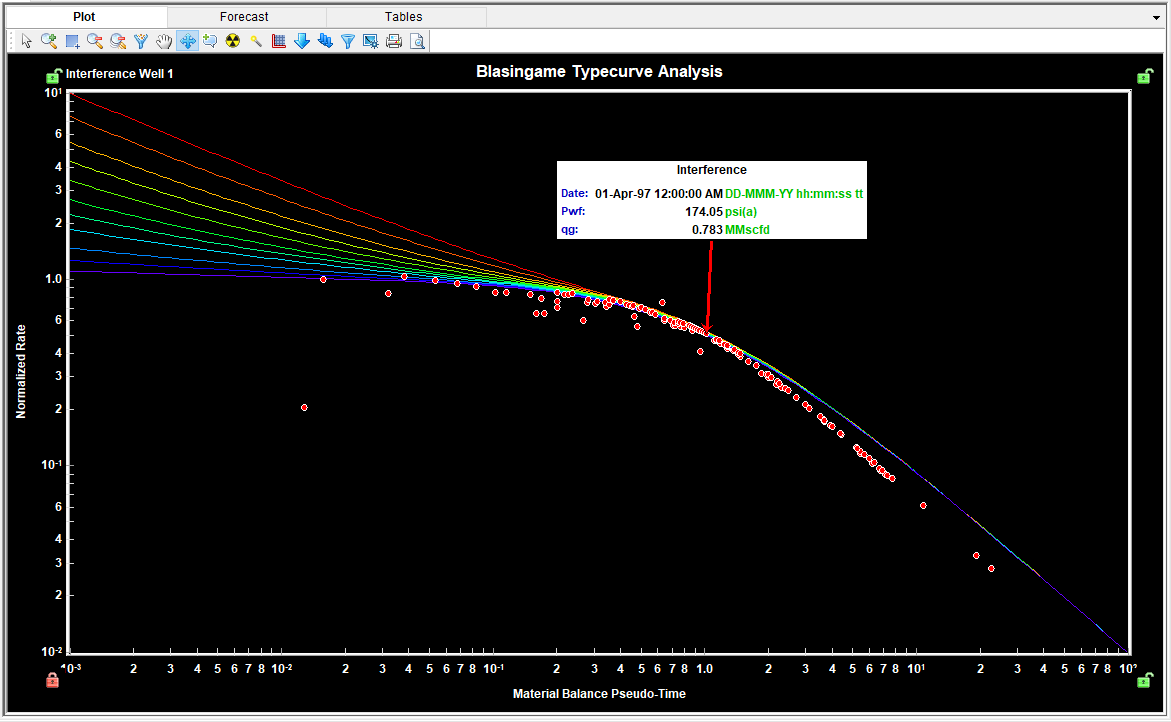

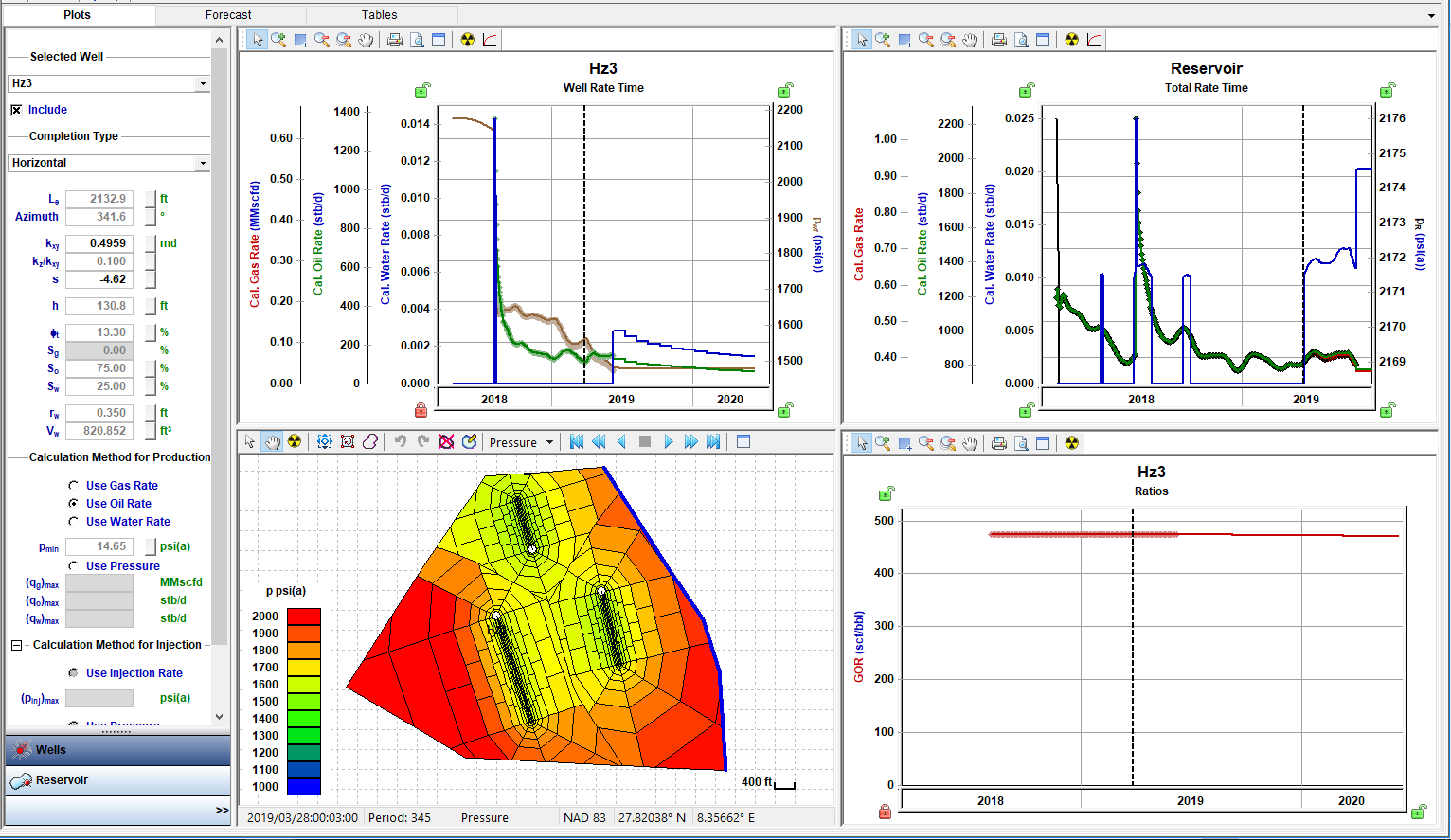

Analysis/ModelingTools: Static material balance is a tool used to determine original hydrocarbons in place when static pressures are available. The Flowing material balance is a powerful tool that can be used for determining the original hydrocarbon in place from flowing rates and flowing pressures without requiring the well to be shut-in. The required data is routinely collected as part of good production practice. Another available tool is Typecurves, which can be used for data quality checking, flow regime identification and reservoir characterisation, as well as determination of hydrocarbon-in-place. The interpretation derived from these different analyses is entered into the appropriate analytical or numerical reservoir model, and the reservoir parameters fine-tuned to obtain a good history-match of the measured flowing pressures and rates. Using this model, a forecast of future production at various specified operating conditions is easily obtained.

Figure 4: Oil Well Above BP

Figure 5: Blasingame Typecurve Analysis

Figure 5: Blasingame Typecurve Analysis

Figure 6: Harmony Enterprise - Multiphase Multiwell Numerical Model

Note that the Rate Transient Analysis, as discussed in this article, is based only on the rates and pressures, and does not explicitly account for geological considerations.

For more details, download and read the full whitepaper.

Request a free demo to experience Harmony Enterprise engineering software's RTA workflows for Conventional wells first-hand.

Silvia Rey Gomez is an Associate Director for Engineering Customer Solutions at IHS Markit.

Posted 19 December 2019.

This article was published by S&P Global Commodity Insights and not by S&P Global Ratings, which is a separately managed division of S&P Global.