From start to finish: Stages of life impact on oil and gas greenhouse gas emission intensity

Governments, industry, investors, and other stakeholders are increasingly interested in understanding the implications of energy transition on the competitiveness of upstream oil and gas operations. Greenhouse gas (GHG) intensity, or emissions per unit of output, has become a key metric of interest. However, GHG emissions associated with oil and gas extraction through end use are variable and dynamic. Not only do GHG emission intensities differ from play to play, by extractive technology, by resource quality, and by operator efficiency, but they also change over time. Emissions during ramp-up and decline of an asset are potentially multiple times higher than during normalized midlife operations. In prior Insights, IHS Markit has explored some of these other sources of variability and uncertainty. This Insight discusses how emission intensity can evolve over the life of an oil- or gas-producing asset and why it matters.

Life cycle impacts life-cycle emissions

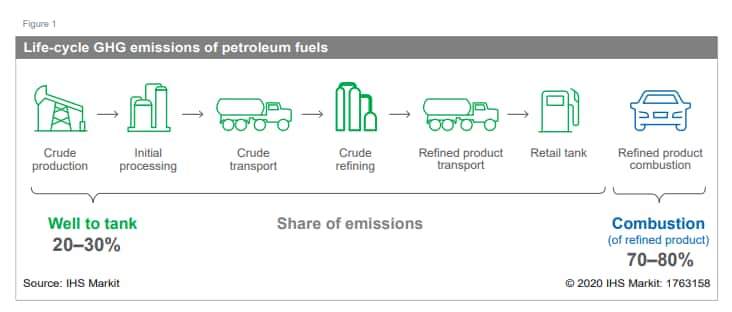

"Life-cycle analysis" typically refers to the accounting of

greenhouse gas (GHG) emissions that arise at each stage throughout

the product's life. For liquid hydrocarbons, the stages typically

include extraction or production, transportation to market,

refining, and ultimately end use in a car or a truck (see Figure

1).

The GHG emission profiles of oil and gas operations, however, are

dynamic and change over the life of an asset. GHG emissions and

emission intensity for oil and gas operations will vary from month

to month or year to year. Moreover, as a play moves through its

life, the emission intensity will undergo distinctive stages. In

some periods of the life of the operations, the difference in

emissions can be significant—emission intensity during ramp-up

and toward end of life can potentially be multiple times higher

than normalized midlife operations. As a result, the stages of life

will impact the shifting competitive pressures of energy transition

on oil and gas resources and the mitigation strategies companies

may pursue.

An illustrative example: Phases of life of an upstream

(offshore) oil operation

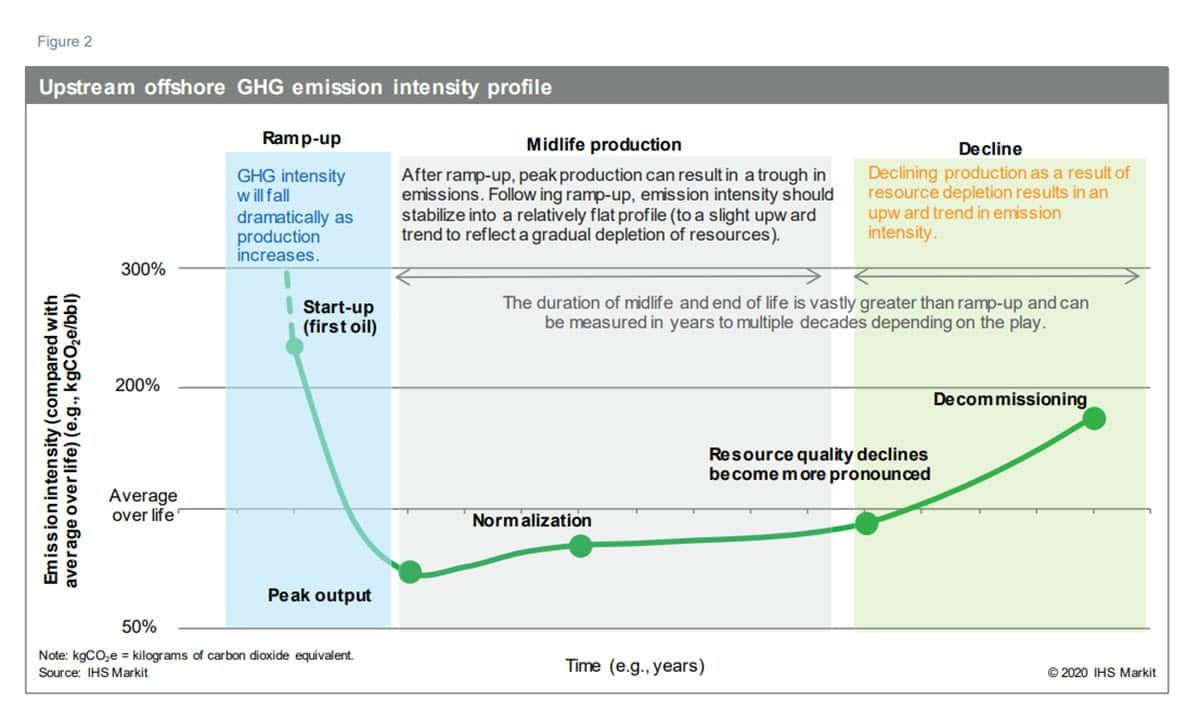

In Figure 2, IHS Markit illustrates three phases of life in the GHG

emission intensity of an oil- and gasproducing operation.*Further

below is a brief description of each stage. It should be noted that

although the relative scale can vary from play to play, this

general profile is likely similar for most oil- and gas-producing

operations. However, the duration of each of these phases can vary

dramatically. While ramp-up is typically the shortest, the duration

of midlife production and end of life can span decades. This

example is drawn from a sample of large offshore crude oil-focused

operations.**

- Ramp-up (early life). The ramp-up of oil-producing operations requires up-front energy expenditures to turn on necessary equipment, drill out, and/or tie into producing wells, as well as run up internal systems. Some emission sources may also be elevated, such as flaring, as key processes come online. The precise profile and ramp-up of this phase of life depend on when accounting for emissions begins—at construction, when power consumption starts, or at first oil. Regardless, until production is achieved, emission intensity would theoretically be infinite (shown in the hashed green line in Figure 2). For our illustration, the solid line represents the profile after oil production begins. The low levels of production at the onset result in very high GHG emissions per unit of output. As production ramps up, typically quickly, the GHG intensity sharply declines. This period of life is typically the shortest lived, and the impact on the emission intensity over the life of an asset can be relatively small.

- Production (midlife). Once production is ramped up and the facility approaches its designed operating capacity, GHG emission intensity stabilizes into a relatively flat profile. A peak in production early in life can result in a trough in emission intensity, as shown in Figure 2. Over this period, the GHG emission intensity is very sensitive to system outages and upsets—periods where much of the energy consumption is maintained but production is interrupted. Keeping a producing facility well maintained and output high helps maximize output and minimize emission intensity and results in a relatively stable emission intensity profile year over year.*** Improvements will occur with the application of new technology or efficiency projects that lead to absolute emission reductions or increases in output or reduced downtime (reliability improvements). The duration of this period can vary dramatically from play to play—from months to multiple decades.

- Decline (maturity). As a producing operation begins to near the end of its life, the emission intensity will increase. This result relates to the quality of the resource that underpins operations. Over time, the productivity or share of hydrocarbons recovered per day will decline, resulting in an upward trend in GHG intensity. Tying in new fields can bring in new high-quality resources and extend the relatively flat midlife production phase. Other technologies can be deployed to mitigate production declines, such as additional pumps that can increase recovery. However, many of these recovery assisting technologies still come with increased energy requirements and contribute to a rise in GHG intensity. Eventually, as the underlying resource declines, emission intensity will increase toward the end of life, until such a time that the level of output no longer justifies economic operation. Although not shown, energy and GHG emissions will occur in decommissioning and reclamation after a project is shut down.

Emission mitigation may require actions beyond just

operators

Because emission profiles are distinct in each stage of life, the

approaches to emission mitigation may differ as well. The

challenges posed by energy transition may also differ depending on

not only where, but when the majority of an oil and gas company's

production sits in its life cycle and the duration that each stage

may span—and thus the significance of each stage. For example,

finding ways to accelerate ramp-up or mitigate energy use (ramping

energy use more attuned to production) can help reduce the ramp-up

intensity and duration, as can ensuring emission mitigation

infrastructure, such as natural gas gathering, is online to meet

supply. Similarly, toward the end of life, greater concern over GHG

emissions could encourage an earlier or more accelerated end to the

economic life of production—truncating the rise in emission

intensity. However, in many oil-producing regions, governments have

imposed rules to preserve and maximize resource extraction. These

rules can include explicit directives on how much resource must be

recovered before an operator can terminate operations and

decommission a facility. In some senses, these legacy rules may run

counter to emerging policies aimed at reducing GHG emissions

(absolute or intensity).

Concluding remarks

IHS Markit is investing in a more sustained GHG Accounting and

Estimation capability—seeking to better understand the GHG

emissions associated with the production through end use of

hydrocarbons in our world today. This accounting of emissions is

known as life-cycle analysis. This Insight, however, suggests that

researchers should also consider how emissions may evolve over the

life of an oil- or gas-producing operation, which may result in

different strategies to improve the emission profile. This result

underscores the complexity in trying to understand the implications

of the energy transition on the oil and gas industry.

* Depending on whether someone is exploring emissions,

cost, or production, there are different definitions for the life

of an oil-producing asset. Examples include land acquisition,

exploration, construction/development, and then decommissioning and

restoration. For this Insight, we are focused on GHG

emissions.

**The figure is derived by averaging the actual GHG

emission intensity profile of a range of facility-based oil

production operations, including from initial stages to near

end-of-life operations. It should be noted that the generation of

this figure is not a trivial endeavor and required modeling fields

that have been in operation for up to nearly a quarter

century

***Looking at emission intensity over shorter periods will

show greater variability in emissions than the annual averages

shown in Figure 1—planned maintenance outages or even unplanned

outages do occur, which can result in emission intensity spikes

over shorter periods

This article was published by S&P Global Commodity Insights and not by S&P Global Ratings, which is a separately managed division of S&P Global.